Free Suggestions For Numbering Prague Mint Coins

Free Suggestions For Numbering Prague Mint Coins

Blog Article

What Is The Reason A Gold Coin Or Medal Digitally 3d-Modeled From A Plaster Cast?

Scanning a maquette for gold coins and medals requires special equipment. It records all dimensions of the model, including details and physical aspects of the model. This digital replication serves various functions in the manufacturing process. the Scanning Process Works

3D Scanning Technology- High-resolution 3D scanners are used to capture the physical dimensions and specifics of the plaster model. These scanners utilize various methods such as laser scanning and structured light to capture exact dimensions and geometrical shapes.

The scanner emits beams of light or lasers onto the model's surface. The scanner tracks the distortions and reflections these beams cause, thus taking in surface information.

Data Collection- As the scanner travels across the surface of the model, it captures a huge amount of points, resulting in an image of the model's shape including contours, details, and contours.

Conversion into 3D Model - The data points collected are processed by software that converts the data into a digital 3D model. The model is a replica of the physical features and dimensions of the maquette of plaster.

Why Create an Digital 3D Model

Digital 3D models allow for precise reproduction of the physical model's dimensions and details. This accuracy ensures that the gold coins and medals will match the design.

Allowing Modifications- Digital models can be easily modified or refined. Designers can modify their designs without affecting the maquette made of plaster.

Compatibleness of Digital 3D Models with Manufacturing Processes. Digital 3D model are compatible with various manufacturing technologies such as CNC machine.

Digital 3D designs are able to be archived and used as documentation. 3D models that are digitally stored can be utilized for future reference, reproduction or historical documentation.

By scanning plaster models and generating 3D digital models, manufacturers and designer can improve their production processes, ensure accuracy of replication and utilize advanced manufacturing technology to make gold medals and coins with a high degree of precision and fidelity. Check out the best Scanning and 3D Modeling Prague Mint gold coins blog info. including 1 10 gold eagle, 100 gm gold biscuit, 50 dollar gold piece, bullion bars gold, gold and bullion, 2000 sacagawea dollar, 2000 olympic, cheerios sacagawea dollar, gold silver shops near me, bullion gold bars for sale and more.

What Is The Process By Which The Janvier Machine Transfer Gold Coins Or Medals From A Master Hub To A Working Hub?

The Janvier Machine, sometimes called a pantograph machine or a reduction device is a tool that is used during the coining process to transfer designs from a Master Hub a Working Hub. This is a brief description of the Master Hub Creation.

The master hub is the original die or mold that carries the exact shape of the medal or coin. The master hub is usually made by using CNC methods of machining or other techniques to ensure accuracy.

Setup for Janvier MachineSetup for Janvier Machine

The Janvier machine comprises a stylus for tracing the design on the hub master, and a cutter that reproduces the design.

The Janvier machine is equipped with a master hub mounted securely. This serves as the template to which the design can be transferred.

Finding the Design

The Janvier stylus is a perfect match for the design's contours as well as the details on the master hub. When the stylus is moved across the surface, it records the design's outline.

Reduce the Design

In parallel, the cutting tool of the Janvier machine reproduces the pattern traced on the working hub which is composed of softer materials than the master hub, like steel or nickel.

The cutting device reduces or copies the design onto the hub of the working wheel in a smaller size or scale in comparison to the hub that is the master hub. This is crucial for the process of coining because it permits medals or coins to be made at the sizes desired.

Accuracy and Precision

Janvier is a high-precision machine that ensures an accurate transfer of designs from the master hub onto the working hub. It can reproduce even the smallest details and contours accurately.

Quality Control

The resulting working hub is subject to quality inspections and a final inspection to ensure the transfered design meets the specifications and accuracy required for the striking process.

More Processing

The hub of Janvier can be used as an tool for striking medals and coins. It serves as a mold or a die to create multiple medals or coins that are blank and have the design transferred.

The Janvier machine plays an essential part in the production process because it permits the exact replication and resizing of intricate designs on medals and coins from a working hub into a master hub. Working Hubs are utilized to produce large quantities of coins or medals through the strike process. Follow the recommended janvier processing Czechoslovakia gold medals website tips. including 24 karat gold coin, 2000 sacagawea dollar, gold silver shops near me, george washington gold dollar coin, gold biscuit buy, 20 dollar gold coin, 1oz gold price today, cost of silver coin, saint gaudens double eagle, platinum coins and more.

How Are High-Quality Gold Bars Weighted, Sized, And Prepared To Be Mint?

The process of making gold blanks is meticulous to ensure that the gold coins or medals produced are consistent and accurate. Learn the process and how it is performedPreparation of the process Gold Material Selection- Gold that is of high purity is used for the production of blanks. The gold is usually refined until it meets the purity standards required for coinage.

Gold Blank Production- The gold is shaped into blanks by a process called blanking or blank-cutting. Blanking is cutting the gold into disks of planchet size or coin size with the help of stamping or special machinery.

Precision Measurement and Weighing

Weighing. Each blank needs to be individually weighed in order to satisfy weight specifications for the coin or coin. This process ensures that every item contains exactly the amount of gold required for each denomination.

Measurements- Each blank is measured to make sure that it complies with the specifications of the design and is uniform.

Inspection and Control of Quality

Visual Inspection- Every blank is visually inspected to detect any imperfections on the surface, irregularities or impurities which could impact the overall quality.

Rejecting Blanks that Are Not Conforming To ensure consistency, we reject blanks that do not conform to the specifications for dimensions, weights, or quality standards.

The Reasons For Preparation

Consistency of Minting Process - The uniformity of the process is assured by precisely weighting and measuring blanks. A uniform weight and size leads to uniform striking and producing medals or coins that are of equal quality and value.

Accurate Gold Content: Each blank is precisely weighed to ensure that the final coin, or medal, contains the exact amount of gold intended. This guarantees accuracy in terms of value and purity.

Uniform Blanks can prevent variations. Uniform blanks can prevent changes in weight or size that could affect the value of a medal or coin's value, or legality in circulation.

Quality Assurance- Strict quality control measures throughout blank preparation will ensure that only top-quality, non-defect blanks are used in the process of minting, which reduces the possibility of defects in the final product.

Legal Compliance - The coins are designed to be used for circulation or as commemorative. They must comply with legal requirements along with requirements and standards established by regulators or mints.

Making gold blanks of top quality and consistent are crucial steps during the process of coining. They guarantee the quality and precision of gold coins that are high-value and medals. Check out the recommended gold blanks for Czechoslovakia gold medals site recommendations including silver price jm bullion, 24k gold coin, 2000 gold dollar, today's 1 oz gold coin price, gold bullion for sale, gold quarter, sovereign british coin, gold buy bullion, gold penny, gold medals michael phelps and more.

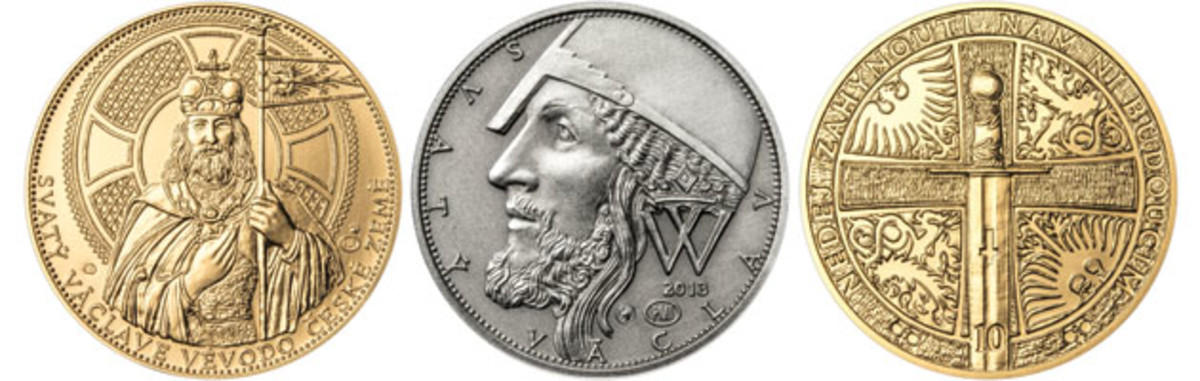

Why And How Are Limited Edition Or Collectible Gold Coins Each One Of Them Individually Are They Numbered?

This helps guarantee authenticity, exclusivity and enhance the appeal of limited edition or collectible gold coins. The how and the reason of this numbering.

Sequential numbering- Each limited edition or collectible coin is assigned an individual number. The numbers are usually stamped or engraved on the coin's surface or edges. The number signifies the coin's position within the series.

Certificate of authenticity. The coins will come with a certificate of authenticity, which is a match to the coin’s unique number. The certificate confirms that the coin is authentic. It provides details about its series, the metal content, and the minting.

There are a variety of reasons to number each coin individually

Authenticity Assurance – Each number is a unique identifier which ensures the authenticity of the coin in the limited series. Each number acts like a unique identifier and ensures that a coin is authentic.

Rareness and exclusivity- editions with unique numbers are perceived as more scarce and exclusive. Coins with numbers are frequently sought by collectors due to their limited availability. This increases their worth.

Coins with a Collectible Appeal are considered collectible in that they allow collectors to track and display specific numbers in the sequence. Significant numbers or those with lower values in the sequence might be considered to be more desirable or desirable.

Individual Numbering for Collectors can encourage collector engagement and a desire in the completion of sets or getting particular numbers. Collectors might be motivated to search for specific numbers based on their personal preferences, or simply because they have achieved a significant achievement.

Potential for resales and value- Coins with unique serial numbers can be more valuable on secondary markets, especially in the event that their serial numbers are smaller or belong to a highly sought-after collection. These coins are valued for their rarity or their uniqueness to collectors.

The ability to track and document a coin's history - Numerical coding helps in the tracking and documentation of a coin's past, assisting in provenance and verifying it on the market for collectors.

In addition to the fact that they are authentic and exclusive, issuing mints or collectors of gold coins can enhance their value by individually identifying each coin. This allows them to create an individual piece in a collection that's rare or special. These numbered coins often hold an important significance and are valuable in the world of Numismatics. Follow the most popular Czechoslovakia gold coin numbering more examples including liberty head nickel, 2000 p gold dollar, congressional gold medal, $5 gold piece, order gold coins, gold and coin shops near me, gold price jm bullion, gold and bullion, gold sovereign coins, sell gold and silver near me and more.